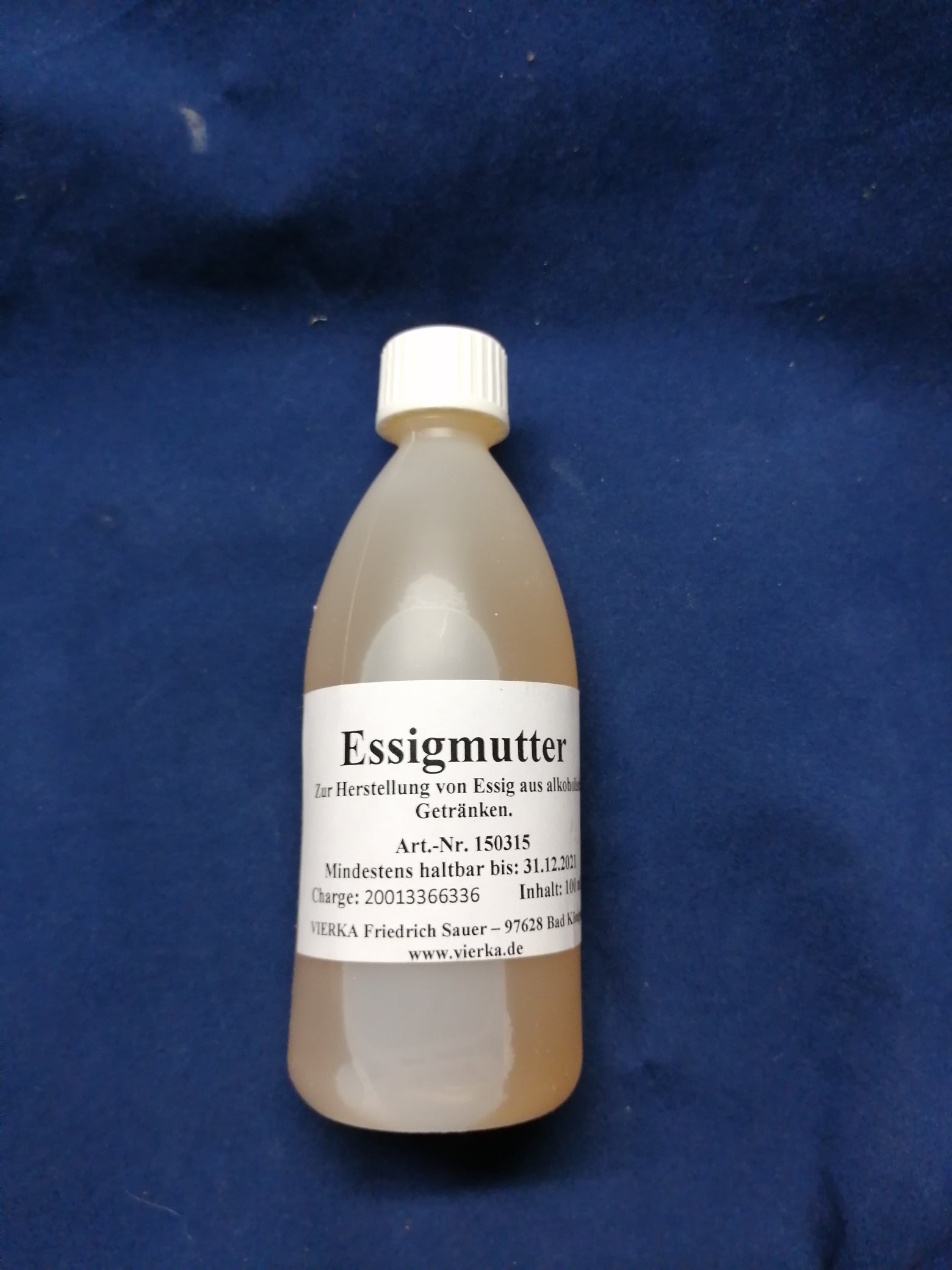

Description

Mother of vinegar culture

For the production of vinegar from alcoholic beverages

By converting the alcohol, a light grape or fruit wine becomes

(not more than 10% by volume, otherwise dilute with water) vinegar produced.

The base wine should be unsulphured or only lightly sulphured.

With good ventilation, the test is performed at a temperature of 25-30°C.

100 ml is enough for 1 liter of wine.

After conversion, this batch is sufficient for 10 liters of wine (and so on). The batch can be further propagated after approximately 1-2 weeks.

Contents: 100ml

Home vinegar production:

Making vinegar at home is far from being as simple as making wine. The bacteria that convert the alcohol into acetic acid are sensitive to their environment, especially temperature. Temperatures must be kept constant at around 25-30°C. Yeast cells, on the other hand, are not significantly affected if the temperature drops to 10-15°C.

1. Starting material:

Vinegar can only be made from alcoholic beverages (fruit wine, grape wine) that are healthy or at most slightly vinegary; the alcohol content should also not exceed 11-12% ABV (no dessert wine). Furthermore, the beverages should ideally be unsulphured or only very lightly sulphured, as this weakens the acetic acid bacteria and significantly delays or even prevents the conversion of alcohol to acetic acid.

2. Pasteurize:

For a high-quality vinegar, it is recommended to warm the wine (very briefly) to about 60°C (no higher) to kill any unwanted microorganisms. At higher temperatures, the alcohol content would evaporate.

3. Inoculation with a vinegar culture (vinegar bacteria):

Vinegar bacteria thrive in warm conditions, meaning temperatures around 28-30°C are ideal. If the beverage has been pasteurized, the temperature must first drop to about 30°C before adding the vinegar culture. It's best to proceed gradually. Since the bacteria can only adapt to their environment slowly, it's advantageous to add the culture to one liter of the beverage, cover the container with a cotton ball, and place it in a warm spot. The container shouldn't be full, as it should be swirled or shaken daily. The bacteria need oxygen to convert the alcohol into acetic acid. Only after a week should this one-liter bottle be divided into approximately five liters, thus increasing the culture. After another one to two weeks, the culture should be increased further in stages (to 10 liters, then 20 liters, etc.).

4. Fermentation vessel:

Our Rondellas with stainless steel spouts (VR51026 or VR51031) are best suited for this purpose. The fermentation vessels should always be only partially filled and sealed in a way that allows oxygen to enter (gauze or a linen/cotton cloth); fermentation locks are unsuitable. If significant temperature fluctuations occur, the vinegar production may be temporarily interrupted, and it will take a long time for the bacteria to regenerate.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.